Lockout / Tagout (LOTO) - Enable safer machine interventions

Every year, thousands of people in Europe are injured during repairs or maintenance work on industrial machinery. A major cause of these accidents is unsecured power sources. The LOTO (Lockout/Tagout) system is a modern opportunity to prevent risk situations during maintenance work.

ID Process: Brady Silver Partner Achievement

1. What is Lockout/Tagout?

Maximise workplace safety, and protect employees with our complete Lockout/Tagout solution. We work with manufacturers worldwide to optimise existing, and to implement new lockout programmes from scratch.

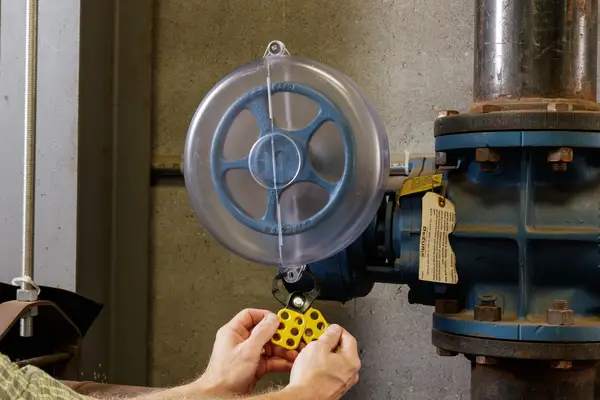

- Lockout/Tagout prevents workplace accidents by completely and temporarily isolating machinery from its energy sources. The procedure and related tools stop machine movement and premature machine energisation while interventions are ongoing.

- Lockout/Tagout can effectively prevent maintenance accidents related to machine energy and moving machine parts. In addition, its visual presence in the workplace helps foster a strong safety culture aimed at sending every employee home safely, every day.

Brady - Lockout Tagout complete solution

2. Lockout/Tagout Compliance

EUROPE

Directive 2009/104/EC (formerly directive 89/655/EEC of the Council from 30 November 1989) specify the minimum requirements for safety and health protection for workers using work equipment at work. Paragraph 2.14 lays down that “every piece of equipment must be fitted with clearly visible devices with which it can be separated from every energy source”. Paragraph 2.15. lays down that “Work equipment must bear the warnings and markings essential to ensure the safety of workers”.

EN ISO 14118 (2018-07) norm of Safety of machinery (is the successor to DIN EN 1037 2008-11) related to the equipment’s safety defines the measures regarding the energy isolation of machinery and the power dissipation to prevent hazardous equipment re-energising. It assures a safe and secure intervention within a risk-prone area.

AUSTRIA

AschG – ArbeitnehmerInnenschutzgesetz – Federal Act on Occupational Health and Safety

AM-VO – Arbeitsmittelverordnung (Ordinance on Work Equipment and Tools) – Regulation of the Federal Ministry of Commerce and Labour on protection of employees while using work equipment paragraph 1, §17 (1).

FRANCE

UTE C18-510 (electrical applications): Lockout of apparatus for service and maintenance to lockout equipment is to carry out the necessary procedures to ensure that the equipment is placed and maintained in a safe position; to prevent its activation and label that the isolated equipment must not be operated. The employer must ensure that all safety procedures are strictly implemented and regularly reviewed by appropriate means. Employees must use all necessary tools to carry out maintenance.

Best practice document developed by INRS (Institut National de Recherche et de Sécurité) in November 2011: ED 6109

- Décret 2010-1016 refers to the obligations of the employers for temporary or permanent electrical installations usage

- Labour code (article R4215-10) refers to the identification of the conductors

- Décret 2010-1018 refers to the prevention of electrical risks in work environment, décret 2010- 2118 refers to the operations done on electrical installations.

- Labour code (article R 4544-5): the part of the installation on which work (de-energised) is done must be identified and locked.

- Arrêté of April 26, 2012: Every operation on electrical equipment must follow the new norm NF C 18-510. Article 1 says that this norm is now included into the French Code of Labour.

GERMANY

BetrSichV 2015 (Ordinance on Industrial Safety and Health) Ordinance concerning the protection of safety and health in the provision of work equipment and its use at work and maintenance processes. Extract from BetrSichV 2015

§ 8 Protective measures in case of hazards caused by energies, start-up and stoppage

Paragraph 3: “Command devices which have an influence on the safe use of the means of work shall in particular be secured against unintended or unauthorised operation. Paragraph 4: “Work equipment may only be intentionally put into operation. If necessary, the startup process must be safely prevented.

§ 10 Maintenance and modification of work equipment

Paragraph 3: The employer must take all necessary measures to ensure that maintenance work can be carried out safely. (3) to secure the working area during the maintenance work (6) to avoid hazards caused by moving raised work equipment or parts thereof, as well as by hazardous energies or substances. (9) Provide necessary warnings and dangers messages referring to maintenance work on the work equipment Paragraph 4: Where, in the case of maintenance activities ... are carried out under the threat of energy, the safety of workers shall be ensured during the duration of this work by means of other appropriate measures.

ITALY

The Italian legislation (Direttiva 2001/45/CE del Parlamento europeo e del Consiglio del 27 giugno 2001 che modifica la direttiva 2009/104/EC) concerns the minimum safety and health requirements for the use of work equipment by workers at work.

SWITZERLAND

UVG – Federal Law on Accident Insurance

VUV – Regulation on the Prevention of Accidents and Occupational Diseases title 1, chapter 2, paragraph 1, art. 3; title 1, chapter 3, paragraph 2, art. 30, 31 paragraph 3, art. 37; paragraph 4, art. 43

EKAS Guideline no. 6512 – Work Equipment

These regulations clearly stipulate that during maintenance, adjusting or cleaning of the equipment, it has to be in non-operative state and appropriate devices have to be used to ensure that, for example, a machine is not accidentally switched on.

SPAIN

The Spanish directive (REAL DECRETO 1215/1997, de 18 de julio por el que se establecen las disposiciones mínimas de seguridad y salud para la utilización por los trabajadores de los equipos de trabajo. BOE nº 188 07-08-1997) states the minimum safety and health for workers’ use of work equipment.

UK Only: BS7671:2008

In the UK the Provision of Work Equipment Regulations – Regulation 19 – Isolation from Sources of Energy states: “Every employer shall ensure, that where appropriate, work equipment is provided with suitable means to isolate it from all its sources of energy. Every employer shall take appropriate measures to ensure that reconnection of any energy source to work equipment does not expose any person using the equipment to any risk to his health or safety.

USA (OSHA - OCCUPATIONAL SAFETY & HEALTH ADMINISTRATION

OSHA regulation The Control of Hazardous Energy (Lockout / Tagout) 1910.147 states that it “requires employers to establish a program and utilise procedures for affixing appropriate lockout devices or tagout devices to energy isolating devices and to otherwise disable machines or equipment to prevent unexpected energisation, start up or release of stored energy in order to prevent injury to employees.

ATEX Standpoint

The ATEX directive consists of two EU directives describing what equipment and work environment is necessary to maintain safety in spaces with a potentially explosive atmosphere. This ATEX directive was published on Saturday 29 March 2014, under the reference : Directive 2014/34/EU of the European Parliament and of the Council of 26 February 2014 on the harmonisation of the laws of the Member States relating to equipment and protective systems intended for use in potentially explosive atmospheres (recast) (Text with EEA relevance) - Official Journal of the European Union L 96 from 29/03/2014.

Areas classified into zones (0, 1, 2 for gas-vapor-mist and 20, 21, 22 for dust) must be protected from effective sources of ignition.[1]¯ Equipment and protective systems intended to be used in zoned areas must meet the requirements of the directive. Zone 0 and 20 require Category 1 marked equipment, zone 1 and 21 require Category 2 marked equipment and zone 2 and 22 require Category 3 marked equipment. Zone 0 and 20 are the zones with the highest risk of an explosive atmosphere being present.

Equipment in use before July 2003 is allowed to be used indefinitely provided a risk assessment shows it is safe to do so.

The aim of Directive 1999/92/EU - on minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres.

This Directive requires employers to introduce technical and/or organisational measures which (a) prevent the formation of explosive atmospheres and/or (b) prevent the ignition of explosive atmospheres and/or (c) reduce the effects of an explosion so that there is no longer a risk to workers.

Several of Brady’s lockout devices and padlocks meet the ATEX standpoint. These are highlighted in the brochure.

3. Lockout/Tagout Best Practice Videos

Brady Group Lock Boxes & Permit Control Stations

Brady Lockout Tagout Device | All purpose cable lockout

How to Install a Brady Safelex LOTO Device

Brady Universal Valve Lockout

Brady 120 volt snap on breaker

Brady 480-600 V breaker blocker

4. A complete Lockout/Tagout implementation from A to Z

Optimise existing programmes easily, or implement world-class Lockout/Tagout from scratch with our complete offer. Anywhere you want to take your Lockout/Tagout programme, ID Process can aid and support you.

4.1 Best-in-class procedures

Enable safer machine interventions faster, and with maximum confidence, using our Lockout/Tagout services. ID Process Engineers can visit your premises to identify all machine energy isolation points and create illustrated, machine specific, world-wide best practice Lockout/Tagout procedures for your approval.

Best practice Lockout/Tagout procedures guide employees through a series of steps to temporarily, and fully, isolate a machine from its entire energy supply, and to lock it in this isolated state as long as maintenance is ongoing.

Our services include:

- LOTO Audit

- LOTO Procedure

- LOTO Instructions

- LOTO Training

4.2 Block access to any energy control point

Access to any energy isolation point can be blocked temporarily with Brady's complete range of dedicated Lockout/Tagout devices.

Energy isolation points may include fuses, buttons, valves, wheels, levers and other systems that control the flow of mechanical, electrical, hydraulic, pneumatic, thermal, gravitational and stored energy, as well as liquids and gaseous chemicals, hot surfaces and substances. All of these can be turned off, and access can be locked while maintenance is ongoing.

4.3 Optimal procedure management

Stay in full control of your Lockout/Tagout procedures, even at multiple sites, with LINK360 software. The process of managing, creating, updating, reviewing, scaling and communicating visually instructive lockout procedures becomes a matter of clicks.

Easily print your procedures and apply them to the right machine, or send them to relevant employee smartphones and tablets for step-by-step procedure compliance with LINK360 app.

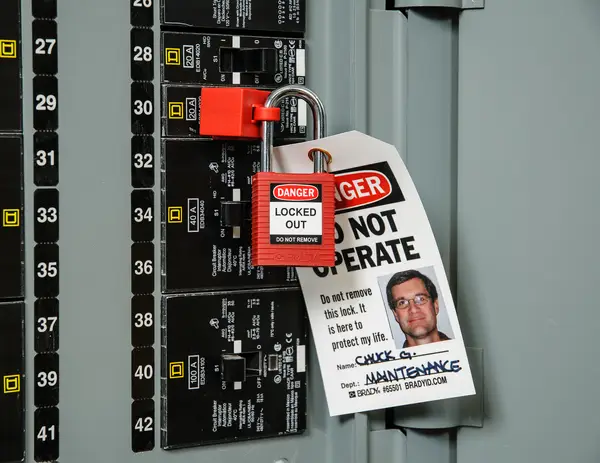

4.4 Best safety padlocks in the world

Easily and reliably lock Lockout/Tagout devices in place, effectively securing a machine’s isolated state until all maintenance workers have finished their intervention. Brady offers quality safety padlock product ranges that can accomodate any Lockout/Tagout programme.

Brady's unique SafeKey padlocks for Lockout/Tagout offer 700% more lock and key combinations than other safety padlocks in the market. They enable elaborate, future-proof Lockout/Tagout programmes, are all key-retaining, and available in optimised versions that fully fit your Lockout/Tagout applications.

4.5 Reliable, long-lasting tags

Easily communicate about ongoing maintenance interventions with fully customisable tags for Lockout/Tagout. We can print and personalise any tag to a picture, an indication of who locked the flow of energy, a phone number, or even a date by when the intervention is expected to be complete. All desired data are printed on long-lasting vinyl tag material that can resist heat, dirt and a range of chemicals.

In addition, you can fully control tag printing with a practical InkJet Safety Printer at your premises to finalise partially printed or blank tag material rolls.

4.6 Efficient accessories

Support the efficient use of Lockout/Tagout in your workplace with practical accessories. Hasps for example allow more maintenance specialists to add their safety padlocks to any Lockout/Tagout device. Custom lockout kits and pouches make standardised tool sets easy to carry, and easy to order anywhere in the world. And Brady's lockboxes provide Lockout/Tagout security for large maintenance operations that may involve multiple work shifts from different teams.

4.7 Highly visible tool distribution

Make all relevant Lockout/Tagout tools easily available in your workplace with custom shadow boards.

Shadow boards promote using the right solutions, and returning them to the right location after maintenance is done. They drastically reduce time spent looking for tools, and considerably increase the availability of Lockout/Tagout in the workplace. In addition, the highly visible Lockout/Tagout shadow boards help promote a safe working culture in any work environment.

4.8 We are here for you

Wherever you want to take your Lockout/Tagout programme, ID Process can guide and support you. Our complete Lockout/Tagout solution includes innovative padlocks with elaborate key planning, dedicated lockout devices, practical software and great services including energy control point identification and best-in-class procedure writing.

Contact us to discuss the needs of your workplace.

For more information on our products,

please contact us!

+4 0727 22 99 21